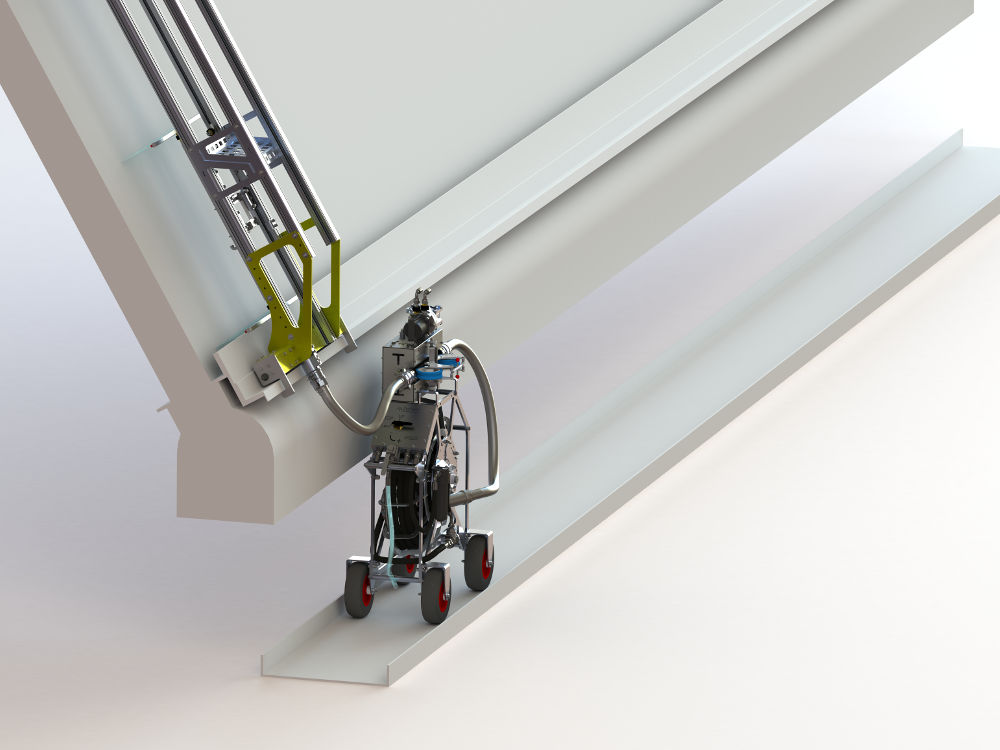

Fin Cleaning System

JS Industries provides the best fin cleaning system in Chennai. We produced the "Fin Cleaning System" which commenced between 2008 and 2010. This product is used in an air-cooled condenser found in a power plant. We opened our second facility in Red hills, 15 kilometers from Unit I, in 2010, and we began producing various fin cleaning systems for various tube bundle types in the heat exchangers in accordance with customer demands. Due to their dependability and great performance, our services and products are widely regarded and in high demand in numerous industries. Our suppliers produce the products we have to offer utilizing first-rate components and innovative methods. To guarantee error-free delivery to the client, we rigorously evaluate the products we offer. Additionally, the dedication of our professionals, our advanced technology-based testing methods, and our quick turnaround times have allowed us to build a solid network of satisfied customers around the country.