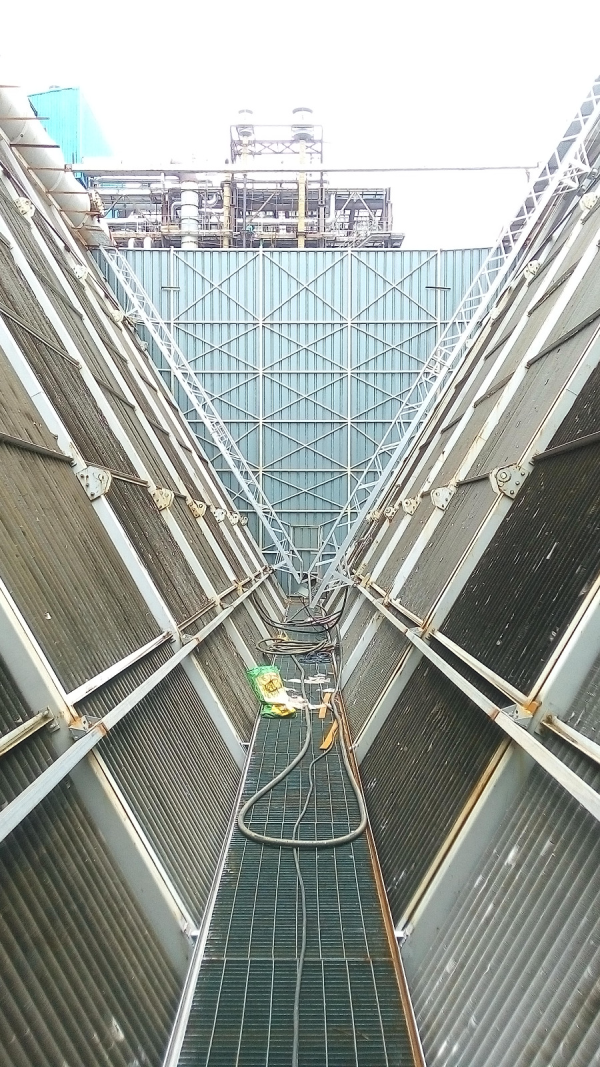

Semi-Automatic fin cleaning system

Motorized nozzle header for up/down movement and horizontal move by manual.

The primary purpose of a fin cleaning system is to remove dirt, dust, debris and other contaminants that can accumulate on the fins over time, thereby improving the overall efficiency and performance of the equipment. Here are the key components and features of a typical fin cleaning system.

The main parts of this system consists of four namely nozzle header, moving ladder arrangement, panel box and rails.

- Nozzle header

It’s a two bunch of nozzles kept at certain distance, driven by a motorized belt system covering entire height of bundle. Each nozzle header consists of bunch of nozzles (Usually 6 to 9 numbers). Total number of nozzles depends on the high pressure pump output flow. The flow of water to these headers is through flexible hose and quick release coupling. - Moving Ladder

This total arrangement of nozzle header and the drive system fixed on the fin cleaning system ladder and the ladder is moving on two rails namely top & bottom rails with use of rollers. - Panel box.

Functioning of panel box is to sense the top & bottom most position of nozzle header and trigger the motor rotation in opposite direction. - Rails

Rails are provided for easy movement of ladders. These rails are permanently fixed on the tube bundle by welding or fastening. Alignment of these rails smoothen the movement of ladders.

Cleaning the finned tube requires just one person to move the ladders from left end to right end and the movement of nozzle header is controlled by panel box (Bottom to Top)

Fixing of rails, assembling of ladders, nozzle headers fixing and cleaning procedures are mentioned in the O & M manual and provided at the time of erection.

Regular cleaning and maintenance of finned surfaces are essential to maintain the efficiency of air-cooled / fin-fan coolers equipment in all the power generation industries and industrial cooling systems.